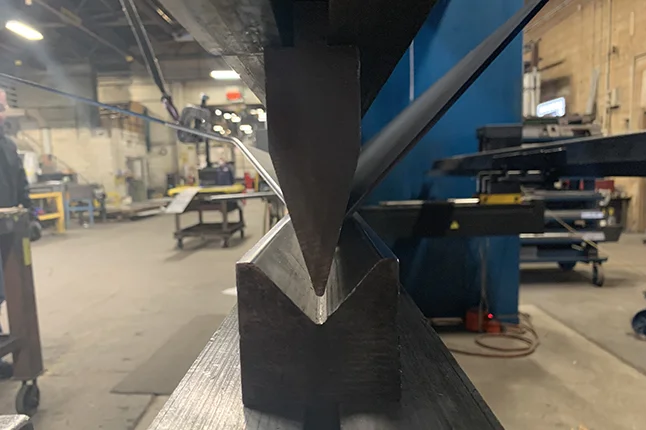

At Valley Metal Works, we take pride in delivering industry-leading Press Brake Forming solutions, combining advanced CNC technology with expert craftsmanship. Whether you need precise bends, complex geometries, or large-scale production runs, our CNC hydraulic press brakes ensure superior accuracy, repeatability, and efficiency—meeting the high demands of modern metal fabrication.

Cutting-Edge CNC Press Brake Technology

Our press brake forming process leverages state-of-the-art CNC hydraulic press brakes, designed to handle a wide range of metals, including stainless steel, aluminum, carbon steel, and heavy-gauge materials. By integrating computerized precision controls and hydraulic force, we deliver unparalleled accuracy, maintaining tight tolerances across every part we produce.

This level of precision is essential for industries requiring flawless fabrication, including aerospace, automotive, construction, and industrial manufacturing. Whether it’s a single prototype or a high-volume production run, we ensure consistency and quality from start to finish.

Why Choose CNC Press Brake Forming?

1. Unrivaled Precision & Consistency

Our CNC press brake forming technology allows us to achieve precise, repeatable bends with minimal deviation. CNC automation eliminates manual errors, ensuring that every component meets exact specifications—critical for industries where precision is non-negotiable.

2. High Efficiency & Scalability

By leveraging CNC programming, we significantly reduce setup time, enabling us to seamlessly transition between projects. This efficiency makes our press brake forming ideal for both custom metal fabrication and large-scale production, ensuring fast turnaround times without sacrificing quality.

3. Versatile Bending Capabilities

From simple bends to complex multi-stage angles, our CNC press brakes can accommodate a variety of bending requirements. Whether you need deep bends, tight radii, or intricate part geometries, our advanced machinery and skilled technicians ensure flawless execution.

4. Cost-Effective & Sustainable Manufacturing

Precision bending reduces material waste, optimizing the use of raw materials and lowering overall production costs. By minimizing scrap and rework, we help our clients save time and resources while maintaining environmentally responsible manufacturing practices.

5. Capability to Handle Diverse Materials & Thicknesses

Our press brake forming services support a broad range of materials and thicknesses, making us the go-to solution for projects requiring strength, durability, and precision. Whether it’s thin sheet metal or heavy-gauge steel, we have the equipment and expertise to get the job done right.

Explore Our Press Brake Forming Solutions

At Valley Metal Works, we’re committed to providing custom metal fabrication solutions tailored to your exact specifications. Whether you need precision bending for small, intricate parts or large, complex assemblies, our CNC press brake forming services deliver outstanding results.

Ready to bring your design to life? Explore our press brake forming capabilities or contact us today to discuss your next project.