In the dynamic world of metal fabrication, precision and versatility are paramount. At Valley Metal Works, we pride ourselves on delivering top-tier metal forming services, and our press brake forming capabilities are a cornerstone of our expertise. This powerful technique enables us to meet the diverse needs of our clients across multiple industries.What is Press Brake Forming?

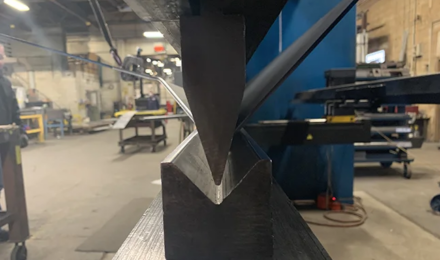

Press brake forming is a metalworking process that involves bending sheet metal into various shapes using a press brake machine. This machine uses a punch and die set to exert force on the metal, causing it to bend at precise angles and creating complex geometries. The process is known for its accuracy and consistency, making it ideal for producing parts that require tight tolerances and intricate designs.

Key Benefits of Press Brake Forming:

- Precision and Accuracy: Press brake forming allows for precise bends and angles, ensuring each piece meets exact specifications.

- Versatility: Capable of handling a wide range of metals, including steel, aluminum, and stainless steel, this process is suitable for various applications.

- Efficiency: Modern press brakes are equipped with advanced CNC technology, which enhances efficiency and repeatability.

Applications of Press Brake Forming

Press brake forming is integral to the manufacturing of various components and products across multiple sectors. Some common applications include:

- Automotive Parts: From brackets and panels to chassis components, press brake forming is essential in producing parts that meet the rigorous demands of the automotive industry.

- Construction Materials: Structural components, such as beams and supports, are often formed using press brake techniques to ensure they can withstand substantial loads.

- Aerospace Components: Precision and reliability are crucial in aerospace, and press brake forming provides the consistency needed for high-performance parts.

- Consumer Goods: Items like metal enclosures, frames, and various household products are often manufactured using press brake forming due to its versatility and accuracy.

Press Brake Forming at Valley Metal Works

At Valley Metal Works, we leverage state-of-the-art press brake machines to deliver high-quality metal forming services. Our experienced team is dedicated to ensuring each project meets the highest standards of quality and precision.

- Agriculture: Press brake forming is used to create durable components for agricultural machinery, ensuring equipment can withstand harsh conditions.

- Construction: We produce robust structural elements and custom metalwork for the construction industry, contributing to safe and reliable buildings and infrastructure.

- Energy: Our press brake forming capabilities are utilized in the fabrication of parts for the energy sector, including renewable energy solutions like wind and solar power.

- Industrial: We provide custom metal forming services for various industrial applications, from machinery parts to custom fabrication projects.

- Automotive: Our precision forming ensures that automotive components are manufactured to exact specifications, enhancing vehicle performance and safety.

Why Choose Valley Metal Works?

Choosing Valley Metal Works for your press brake forming needs means partnering with a team that is committed to excellence. Our advanced equipment, combined with the expertise of our skilled technicians, ensures that we can handle projects of all sizes and complexities. We understand the unique requirements of each industry we serve and tailor our services to meet those specific needs.

Whether you need a single prototype or large-scale production runs, Valley Metal Works has the capability and expertise to deliver exceptional results. Contact us today to learn more about how our press brake forming services can benefit your next project.

Explore our press brake forming capabilities here and discover why Valley Metal Works is the trusted partner for precision metal forming.