Valley Metal Works stands as a premier provider of custom metal fabrication services, offering comprehensive solutions tailored to the pharmaceutical industry. With over 80 years of experience, we specialize in delivering precision-engineered components that meet the stringent standards of pharmaceutical manufacturing.

Comprehensive Metal Fabrication Services

Our services encompass:

- Metal Cutting: Utilizing advanced laser and plasma cutting technologies, we achieve precise cuts across various metal thicknesses, ensuring components meet exact specifications.

- Welding: Our team of seasoned welders excels in both standard and intricate welding tasks, upholding the highest standards of accuracy and efficiency.

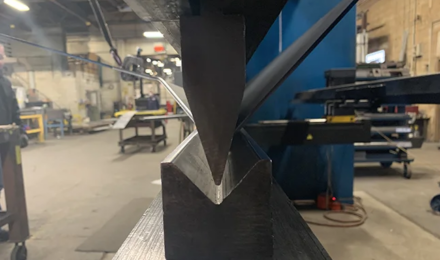

- Press Brake Forming: We offer flexible press brake forming services suitable for a diverse range of applications, streamlining production processes.

- Finishing: Our finishing services include wet spray painting, industrial blasting, and assembly, providing a complete solution from fabrication to final product.

- Sheet & Plate Rolling: Our cost-effective sheet and plate rolling services reduce the need for secondary operations, enhancing production efficiency.

- Engineering & Design: We provide comprehensive engineering and design support, including drawing, 3D modeling, and CAD services, to assist in product development and optimization.

Serving the Pharmaceutical Industry

The pharmaceutical industry is among the most highly regulated sectors in the world, with stringent standards designed to ensure the safety, efficacy, and quality of drugs and healthcare products. Every component used in pharmaceutical manufacturing facilities must meet rigorous hygiene and operational requirements to prevent contamination and maintain product integrity. These standards are governed by entities like the U.S. Food and Drug Administration (FDA), European Medicines Agency (EMA), and Good Manufacturing Practices (GMP).

Key considerations include the need for:

- Sanitary Design: All metal components, including tanks, platforms, and ductwork, must feature smooth, polished surfaces to prevent bacterial growth and ensure easy cleaning.

- Material Compliance: Stainless steel is often required due to its corrosion resistance and non-reactive properties, essential for sterile environments.

- Precision Fabrication: Exact tolerances are critical to ensure seamless integration of components and adherence to performance standards.

- Documentation and Traceability: Fabricated components must include detailed documentation to meet validation and audit requirements.

Valley Metal Works excels in serving the pharmaceutical industry by fabricating custom components that meet these exacting standards. Whether producing platforms and walkways for cleanrooms, custom ductwork for HVAC systems, or storage bins and tanks, our team ensures every product is crafted to the highest levels of precision and compliance.

Advantages of Partnering with Valley Metal Works

Collaborating with Valley Metal Works offers several benefits:

- Quality Control: We work closely with clients to understand their specific requirements, ensuring the final product meets exact specifications.

- One-Stop Shop: Our comprehensive services streamline the production process, reducing the need to coordinate with multiple vendors.

- Customer Service: Our dedicated team prides itself on detailed communication and on-time delivery, fostering strong client relationships.

- Expertise: With extensive experience in small to medium-sized production runs for OEMs, maintenance shops, and engineers, we are well-equipped to handle complex projects.

By choosing Valley Metal Works, pharmaceutical companies can rely on a partner committed to delivering high-quality, custom-fabricated metal products that meet the industry’s rigorous standards. For more information on your next pharmaceutical project, contact us today.