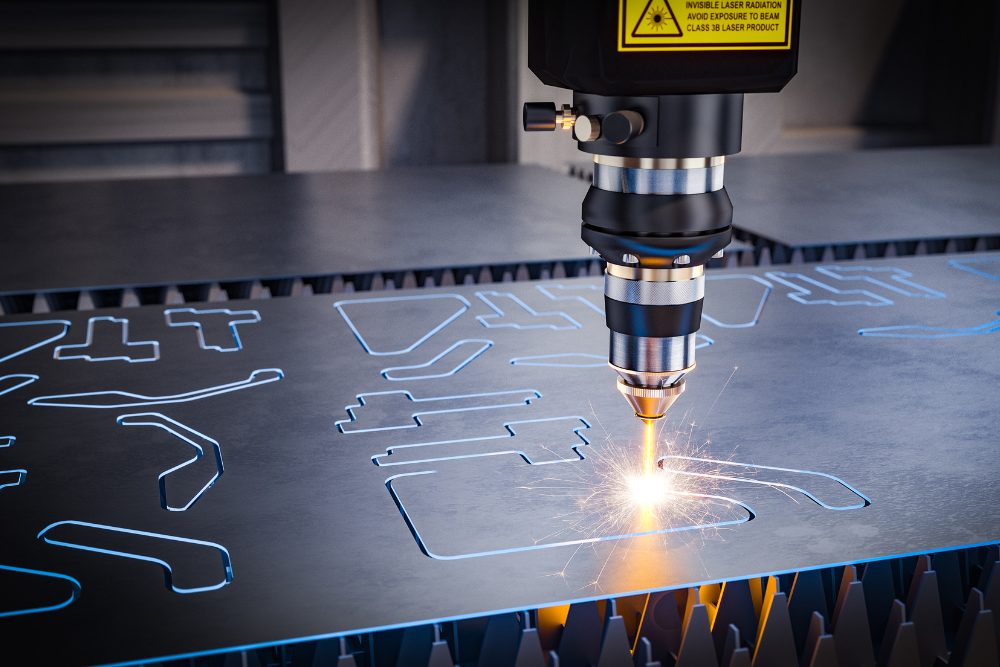

At Valley Metal Works, precision is at the core of everything we do. Our laser cutting and plasma cutting services provide high-accuracy metal fabrication solutions, ensuring clean edges, consistent quality, and optimal efficiency for projects of all sizes. By leveraging the latest CNC laser and plasma cutting technology, we offer tailored solutions that meet the unique demands of various industries, from aerospace and manufacturing to construction and energy production.

State-of-the-Art Metal Cutting Technology

At Valley Metal Works, we utilize advanced cutting equipment, including the Mazak Optiplex 4020 FIBER III, a high-performance 2D laser cutting system designed for exceptional precision and speed.

Key Features of Our Laser Cutting Technology:

- 8kW Fiber Laser – Enables fast cutting speeds while maintaining excellent cut quality on materials like mild steel, stainless steel, and aluminum.

- Flying Optics Design – Allows efficient cutting of complex shapes and contours with maximum accuracy.

- 2 Pallet Changer – Minimizes downtime, allowing continuous loading and unloading of materials for increased productivity.

- Multi-Control Torch – Optimizes cutting efficiency with automatic setup and real-time adjustments.

- Rapid Traverse Rate of 4,724 Inches Per Minute – Enhances throughput for high-volume projects.

Our Cutting Capabilities:

- Thickness: Up to 1-inch thick for steel, stainless steel, and aluminum.

- Workpiece Size & Weight: Handles pieces up to 78-5/8” x 157-3/8” and 3,500 lbs.

Whether you need precision-cut components, decorative metal panels, or structural metal parts, our laser cutting services deliver exceptional quality with minimal waste and maximum efficiency.

Advantages of Laser Cutting at Valley Metal Works

1. Unmatched Precision & Accuracy

Laser cutting allows us to create sharp edges and intricate details with tight tolerances, making it ideal for custom designs and complex geometries. Whether you need prototype development or high-volume production, our CNC-controlled laser cutting ensures consistent, high-quality results.

2. Speed & Efficiency for Faster Turnarounds

Our high-powered laser systems offer rapid processing speeds, reducing lead times and improving efficiency for our clients. Faster cutting means quicker project completion while maintaining exceptional accuracy and minimal rework.

3. Cost-Effective & Sustainable Manufacturing

- Minimized Material Waste – Laser cutting’s precision reduces scrap material, optimizing resource usage.

- Energy-Efficient Process – Fiber laser technology consumes less energy than traditional cutting methods, making it a sustainable solution.

- Reduced Need for Secondary Finishing – The clean cuts produced by laser cutting reduce deburring and additional finishing processes, lowering production costs.

4. Seamless Integration with Fabrication & Welding

Our laser-cut components are designed for easy integration into fabrication, welding, and assembly processes. The precise cuts improve structural integrity, reduce welding requirements, and ensure better-fitting components.

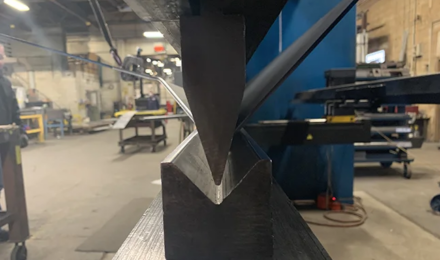

Plasma Cutting: Power & Efficiency for Heavy-Duty Applications

While laser cutting excels at precision work, our plasma cutting services are ideal for projects requiring high-speed processing of thicker materials. Plasma cutting utilizes a high-temperature ionized gas arc to cut through heavy-duty metals, making it a preferred solution for industrial, structural, and heavy manufacturing applications.

Key Benefits of Plasma Cutting:

- Fast & Efficient – Perfect for large-scale industrial projects requiring thick metal cutting.

- Cost-Effective for Thick Metals – More economical than laser cutting for high-volume, heavy-duty materials.

- Highly Durable Cuts – Produces strong and reliable components for industrial applications.

Metals We Work With

At Valley Metal Works, we cut a wide range of materials, including:

Steel & Stainless Steel

- Mild Steel (A36, A572, A516 Grade 70)

- Stainless Steel (304, 316, and other grades)

- AR Series (AR235, AR400, AR500 – abrasion-resistant steel)

Aluminum & Specialty Alloys

- 5052, 6061, and custom aluminum grades

- Hardox and wear-resistant materials for heavy-duty applications

No matter the material or project complexity, our team ensures that every metal cutting job meets the highest standards of precision and performance.

Why Choose Valley Metal Works for Metal Cutting?

At Valley Metal Works, we go beyond just cutting metal—we provide fabrication solutions that help businesses optimize production, reduce costs, and improve product quality.

What Sets Us Apart?

- Advanced CNC Laser & Plasma Cutting Technology – Precision, speed, and consistency in every cut.

- Experienced Team of Fabrication Experts – Decades of industry expertise in custom cutting and fabrication.

- Custom Solutions Tailored to Your Needs – We work with OEMs, engineers, and manufacturers to deliver bespoke cutting services.

- Commitment to Quality & Customer Satisfaction – Every project is handled with attention to detail and industry-leading quality control.

Let’s Cut with Precision – Get Started Today

Looking for a trusted partner for high-precision metal cutting? Whether you need laser cutting for intricate designs or plasma cutting for industrial applications, Valley Metal Works has the expertise and technology to bring your project to life.

Explore our metal cutting capabilities or contact us today to request a quote!